Super Heavy Weight

Home > Products&Service > Super Heavy Weight > Power Pack Unit

Power Pack Unit (PPU)

Equipment to supply Inter Combi or SPMT with electric power or oil pressure

PP-K24

In the switch box of each PowerPackUnit is a touchscreen display installed. On this display, all vehicle or combination data can be entered and checked. Due to the integrated diagnosis system all parameters, operation states and current values can be displayed. Therefore, troubleshooting is much easier than before. Another advantage is the language setting on the screen, with this the whole operating manual can be displayed in the respective national regulator provides the oil flow for the lifting-, steering- and braking systems. It works in an open circuit. Two axial piston pumps supply the oil flow for the drive system. They work in a closed-loop circuit.

For supplying other coupled vehicles with air, like K25H, an air compressor is installed on the Diesel engine. Furthermore, it is possible to connect pneumatic tools or to adapt the air pressure in the wheels.

The industrial computer and the operating and control elements are situated in the stainless steel switch box.

For the connection of the hydraulic and electric supply of the platform vehicles, the respective lines are installed on the right and on the left of the PowerPackInit and equipped with non-spill flat-face screw couplings. Dust caps are available for the protection of the couplings while they are not used. Threr are plug-sockets on both sides for the electic supply and control lines for coupling two or more PowerPackUnits side-by side. The PPU is fixed to the platform vehicle by a coupling colt. Moreover, it can be regulated with two gydraulic cylinders to avoid that it touches the floor when driving over an elevated platform.

PP-K25

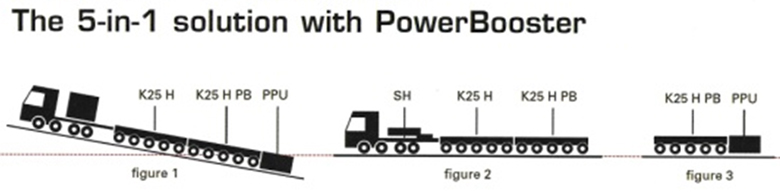

The new K25 H PB is equipped with shiftable drive axies and can be towed at 50miles/h or even be propelled by an equally shiftable PowerPackUnit(PPU), as neede,. This development offers additional traction and thrust force without using an additional thrust machine on transport routes with ascending slope. Furthermore, the K25 H PB can be operated as a self-propelled unit or be coupied to other K25 H platform trailers.

1. As thrust machine : Before driving on a critical ascending slope, the driver starts the PPU with a performance of 150 kW. As soon as the tractor has insufficient power to manage the ascending slope, i.e. speed drops below 9 miles/h, the driving gear starts automatically, thus providing sufficient thrust. Once the slope has been overcome, the additional driving gear shuts off automatically and speed can be increased again in accordance with the road conditions (see fig. 1)

2. As trailer combination in regular traffic : Once the driving gear is switched off, the drive unit can reach a speed of 50 miles/h in the vehicle combination. The K25 H PB also is different to toher types of vehicles because of its strong frame construction, acle compensation of +/-300mm and 60˚steering angle (see fig. 2).

3. For in-piant transports : During in-paint tasks, the drive unit with PPU - with or without K25 H platform trailer - can be uncoupled from the tractor and controlled as self-propelled transport combination via a mobile operating panel. This operating panel controls the gydrostatic drive, lifting and lowering functions, hydraulic steering, brake system as well as the electrical power supply. Short, manoeuvrable and extremely flexible (see fig. 3)!

4. Mechanical "side-by-side" coupling : A further possibility for the in-house transport is the mechanically soupled "side-by-side" combination. Due to the wide supporting base, payloads with a high centre of gravity can be transported.

5. Mechanical "end-to-end" coupling : The PowerBooster can be used as a traction unit at the front or as a thrust machine at the rear part of extremely long combinations (with or without decks). With all these different kind of possible combinations the PowerBooster is an all-rounder of the heavy duty transport.